Case Study – DAF

NBT’s improvised DAF system

Existing DAF

Major meat processor in NSW has been facing a massive challenge in their operation. An increase in consumer demand and an expanding business saw more wastewater in its DAF than ever before. The DAF was designed to handle 3 kL/hr of wastewater a day. Now, it is processing three times or more of that amount. The overwhelming contamination was a health and safety hazard and from a business perspective, a financial liability.

NBT’s Improvisation

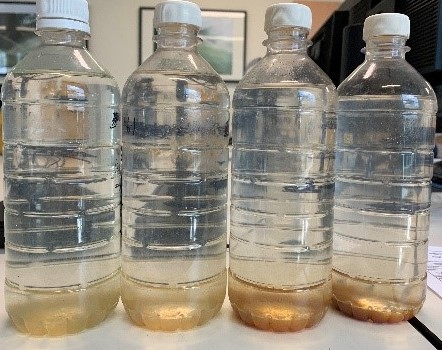

With the installation of the NBT trial machine, results showed great improvement in sludge density (Left), which allowed for easier skimming in comparison to the existing DAF (above) and a considerable reduction in contaminant levels. NBT’s system can be easily retrofitted or integration to an existing system.

Key Results

· Almost 4 times greater BOD removal in Kg/hr

· More than 80% TSS removal

· Visibly better overall wastewater clarity

· Up to 70% reduced energy consumption